Winter driving and off-road operations demand reliable traction, especially in harsh, icy, or snowy conditions. Whether you rely on ATV snow chains for rugged terrain or tractor snow chains for heavy-duty agricultural work, durability is a key factor in performance and safety. But what exactly makes certain snow chains withstand hard conditions while others fail prematurely?

1. High-Quality Steel: The Backbone of Durable Snow Chains

The primary material used in heavy-duty ATV snow chains and tractor snow chains is high-tensile steel. This type of steel is alloyed with carbon and other elements to enhance strength and resistance to wear. Unlike standard steel, high-tensile variants do not easily deform under pressure, making them ideal for hard winter conditions.

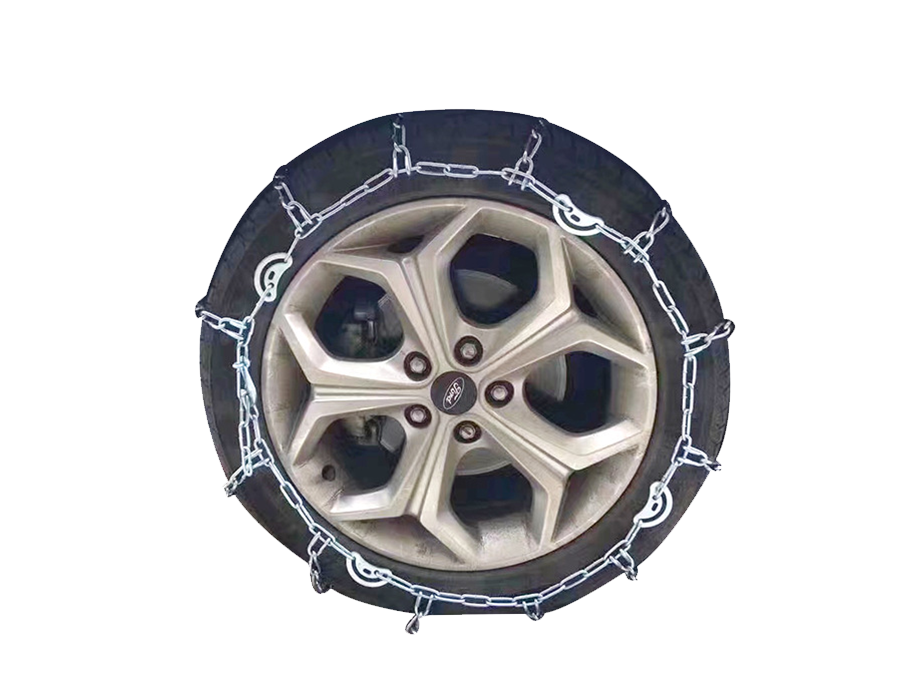

For ATV snow chains, manufacturers often use a combination of hardened steel links to prevent stretching and breaking during aggressive off-road use. Similarly, tractor snow chains require reinforced steel components to handle the immense weight and torque of farm machinery.

2. Reinforced Cross Chains and Links for Enhanced Strength

The cross chains—the horizontal components that provide direct contact with the ground—are critical for durability. In high-performance ATV snow chains, these cross chains are often thicker and heat-treated to resist abrasion from rocks, ice, and rough terrain.

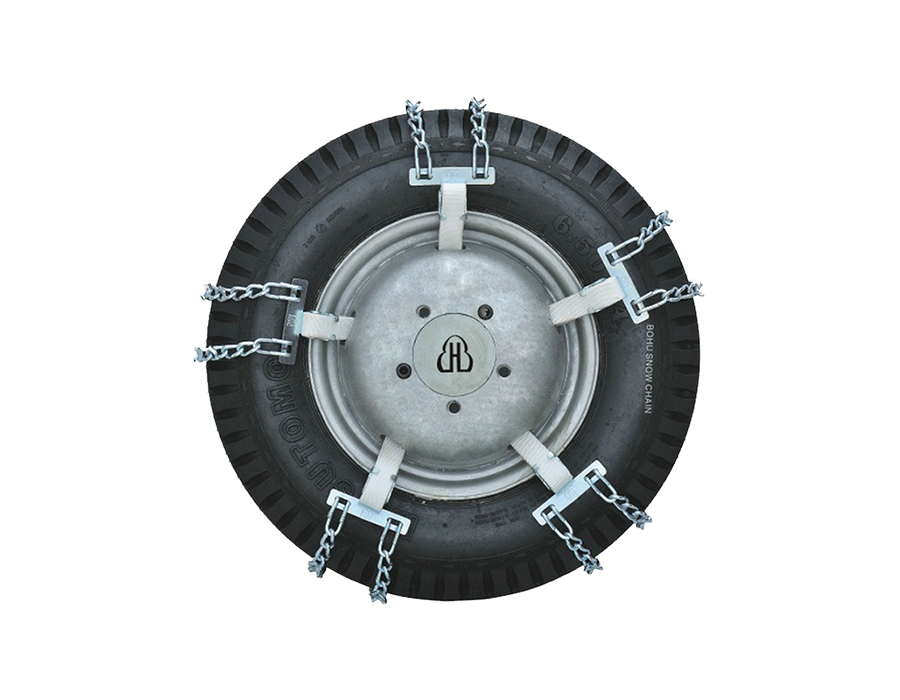

For tractor snow chains, cross chains must support not only the vehicle’s weight but also additional loads like plows or trailers. Many premium tractor snow chains feature double-twist or square-link designs, which distribute pressure more evenly and reduce the risk of chain failure.

3. Corrosion-Resistant Coatings for Longevity

Snow chains are constantly exposed to moisture, road salt, and chemicals, pilot to rust and degradation over time. To combat this, high-quality ATV snow chains and tractor snow chains undergo specialized coating processes such as:

Galvanization: A zinc coating that prevents rust and extends chain life.

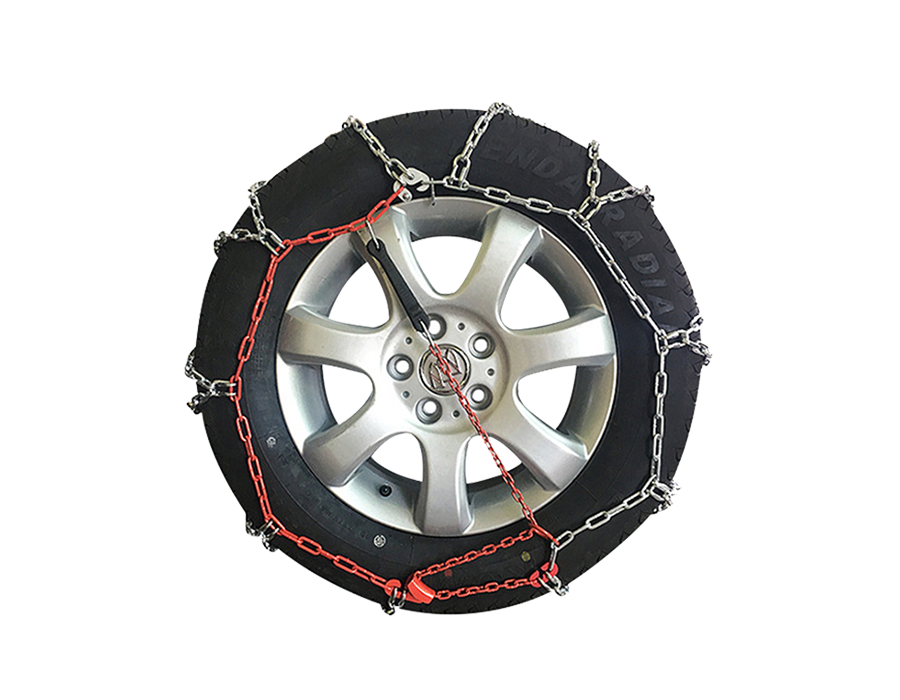

Polymer coatings: Some ATV snow chains use plastic or rubberized layers to reduce metal-on-metal wear.

Powder coating: A durable finish often applied to tractor snow chains for extra protection against harsh farming conditions.

These treatments ensure that the chains remain functional season after season, even with frequent use.

4. Good Chain Tensioning Systems to Prevent Wear

A common cause of premature snow chain failure is improper tension. Loose chains can slap against tires, causing damage to both the chains and the vehicle. High-end ATV snow chains and tractor snow chains incorporate self-tensioning mechanisms or heavy-duty rubber tensioners to maintain a secure fit.

For ATV snow chains, quick-adjustment cam locks or elastic tensioners help keep the chains snug during high-speed off-road travel. Meanwhile, tractor snow chains often use heavy-duty ratchet systems to ensure stability under heavy loads.

5. Impact-Resistant Design for Rough Terrain

Off-road and agricultural environments subject snow chains to hard stress. ATV snow chains designed for rocky or uneven trails often feature reinforced side chains to prevent snapping under sudden impacts. Similarly, tractor snow chains built for muddy fields or icy roads use interlocking link patterns to absorb shocks without deformation.

When selecting ATV snow chains or tractor snow chains, material quality and construction play a crucial role in durability. High-tensile steel, reinforced cross chains, corrosion-resistant coatings, proper tensioning systems, and impact-resistant designs all contribute to a product that lasts through hard winter conditions.

Would you like recommendations on maintaining your snow chains for an extended lifespan? Stay tuned for our next guide on winter chain care tips!

English

English русский

русский 中文简体

中文简体